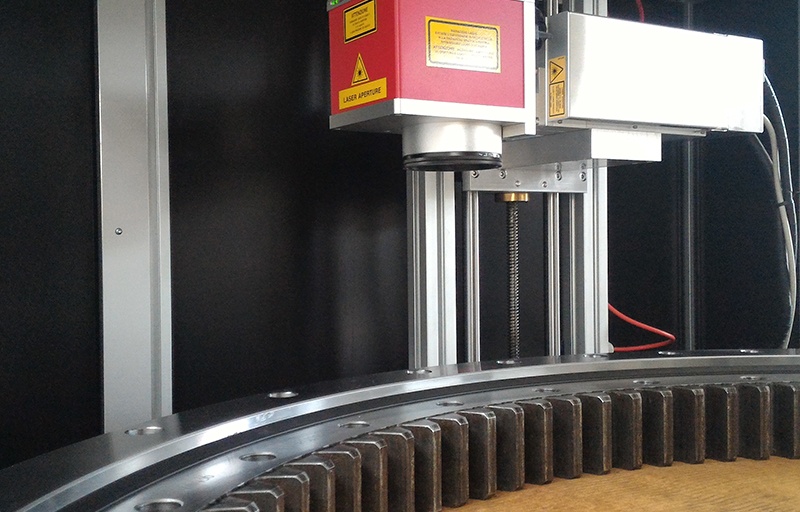

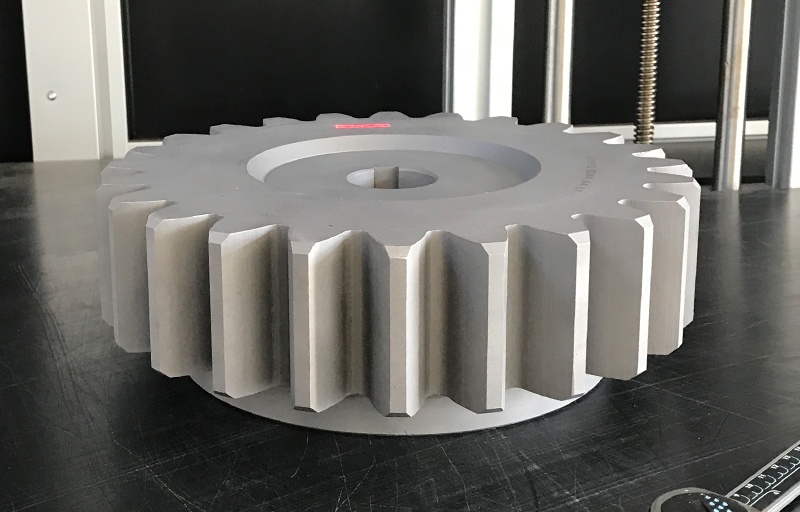

LASER MARKING

Each Evolmec item is marked with code and company logo to guarantee the product and in order to make easier to trace the bearings. Moreover, Evolmec offers a laser market service on behalf of a third party.

For further information please contact our engineering department.

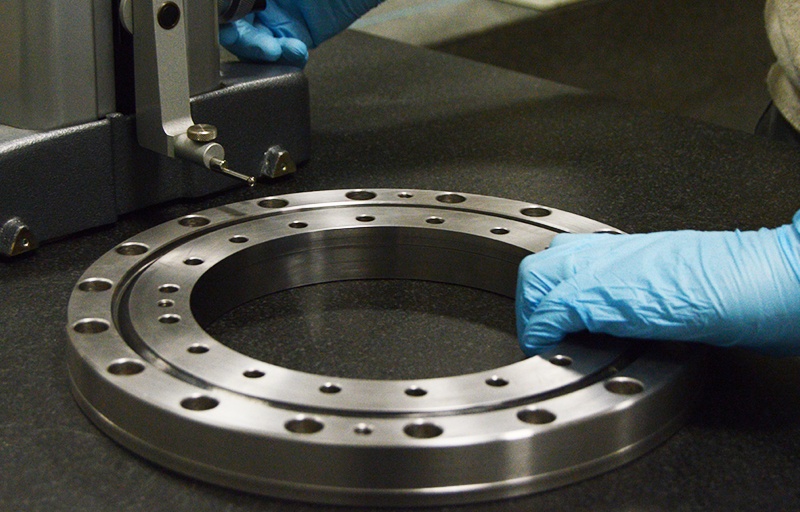

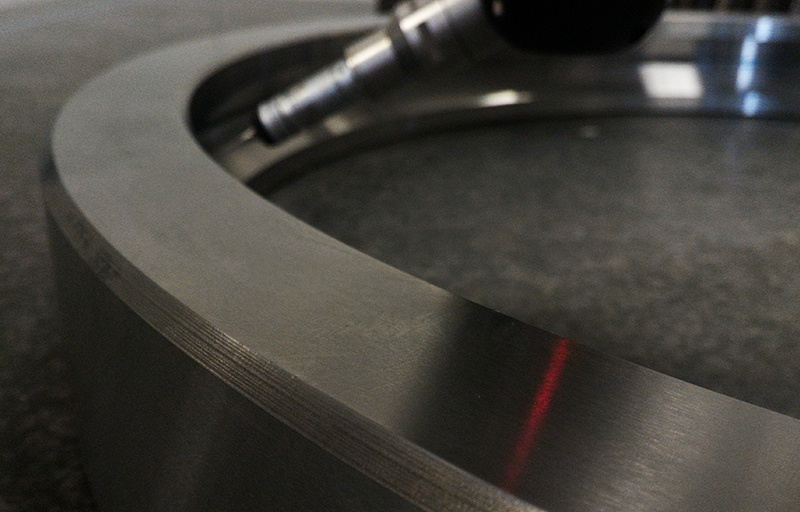

MEASURING

Evolmec has its own metrological lab, equipped with high tech instruments in order to test its bearings.

Evolmec offers a measuring service on behalf of a third party for every mechanical component. For further information please contact our engineering department.

MEASURING EQUIPMENT

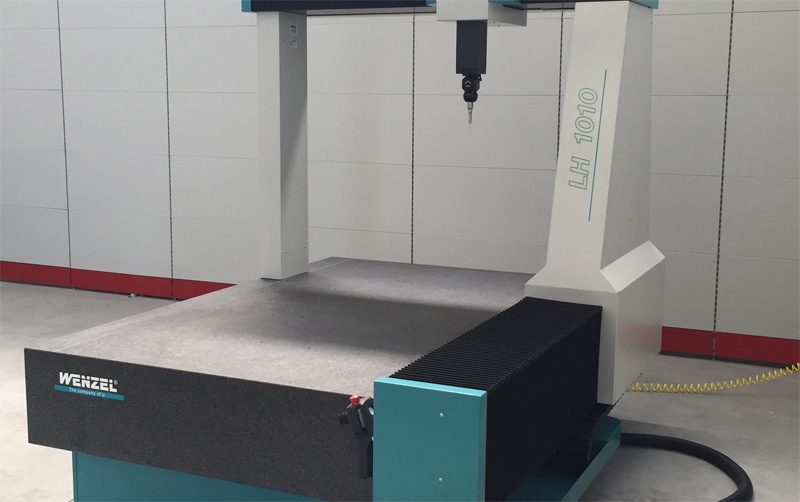

COORDINATE MEASURING MACHINE

WENZEL LH1010

WORKING AREA DIMENSIONS

X axis: 1000 mm

Y axis: 1200 mm

Z axis:1000 mm

RENISHAW PH10M MOTORISED INDEXING HEAD

RENISHAW TP200 CONTACT PROBE

MEASURING PRECISION: Maximum permissible error = 0,0025 mm

(according to DIN EN ISO 10360-2 referring to a Ø4 x 21mm stylus)

WORKING TEMPERATURE: 15°-30°

HEIGHT GAUGE

TESA MICRO-HITE 600

Self-contained design made to measure in 1 or 2 coordinate directions – For length measurements in the form of internal, external, height, depht, step and distance dimension of geometric elements with flat, parallel or cylindrical surfaces

Results output in conformance with ISO 1101.

Stroke lenght: 615mm

MEASURING PRECISION: Maximum permissible error = (2 + 3L) μm (L in m)

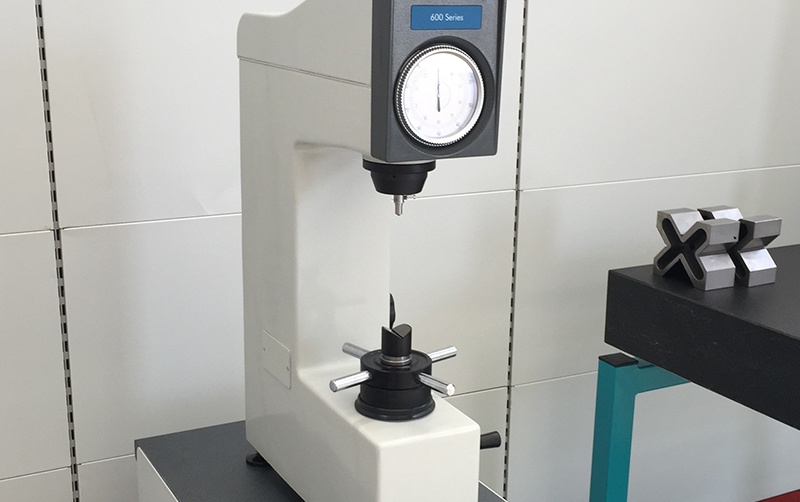

ROCKWELL BENCH HARDNESS TESTER

INNOVATEST 600 SERIES

Manual and analog version, without data output

Resolution: 1HR

Precision: according to EN-ISO 6508, ASTM E-18

Display indications: HRC, HRB

Maximum piece height: 170mm

Maximum arc depth: 135mm

DIGITAL INDICATOR

RUPAC DIGITRONIC SERIES

Measuring range: 0 -12,7mm

Resolution: 0,001mm

Precision: 8μm